Advance warehouse management – Item Creation process in Microsoft D365 F&O – Part 1

Hello everyone, in this series of Blog, we are going to learn about the Advance warehouse management in D365.

What is Advance Warehousing Process?

The day-to-day transactions in the advanced warehouse are a bit different than in a normal warehouse. Workers in the advanced warehouse use mobile devices to move stock from one location to another. Here location doesn’t mean just the location, we can move it from one warehouse to another. So, instead of sitting in one place, workers can move around the warehouse to pick up or put the stock. In Advance warehouse management, the visibility of the stock is very clear. Workers can see where the stock is in the warehouse and in what quantity. This results in Streamlined warehouse operations, reduced inventory carrying costs, and thus improvement in customer satisfaction through faster and more accurate order fulfillment.

In this blog we will learn about the basic setups required for the Advanced Warehouse Management process. These setups may vary depending on the business scenarios. For an item to work in an Advance warehouse scenario, there are some prerequisites that we need to do first. The following are the setups that we need to configure:

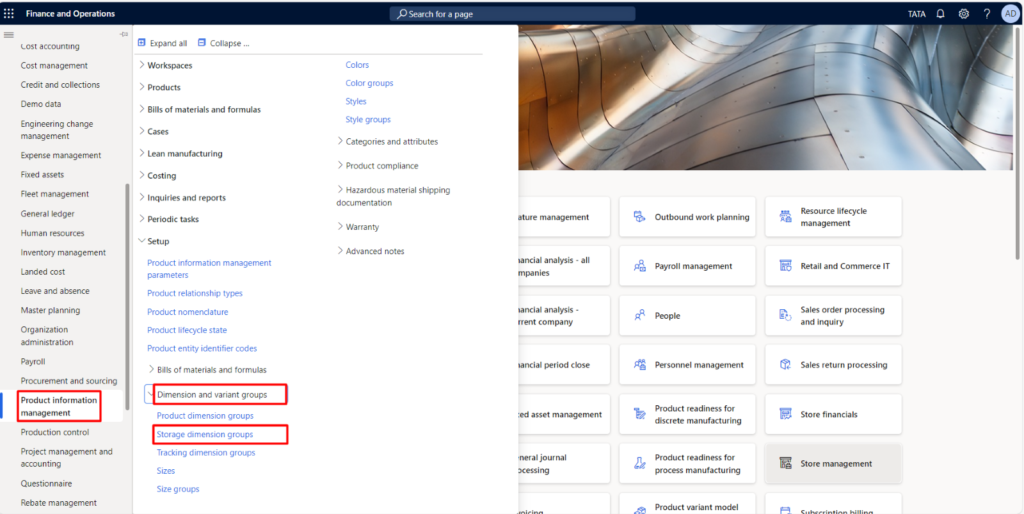

- Storage dimension group

Path: Product Information Managementà Dimension and Variant Groupsà Storage Dimension Groups.

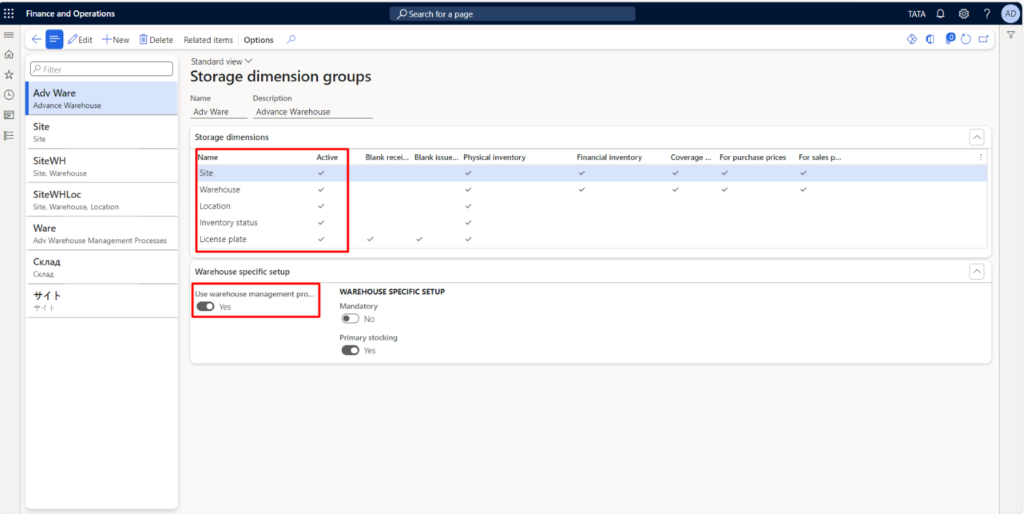

In the Storage dimension group, activate the “Use warehouse management process.”

Once you activate the use warehouse management process, the Location, Inventory Status, License Plate will be automatically activated.

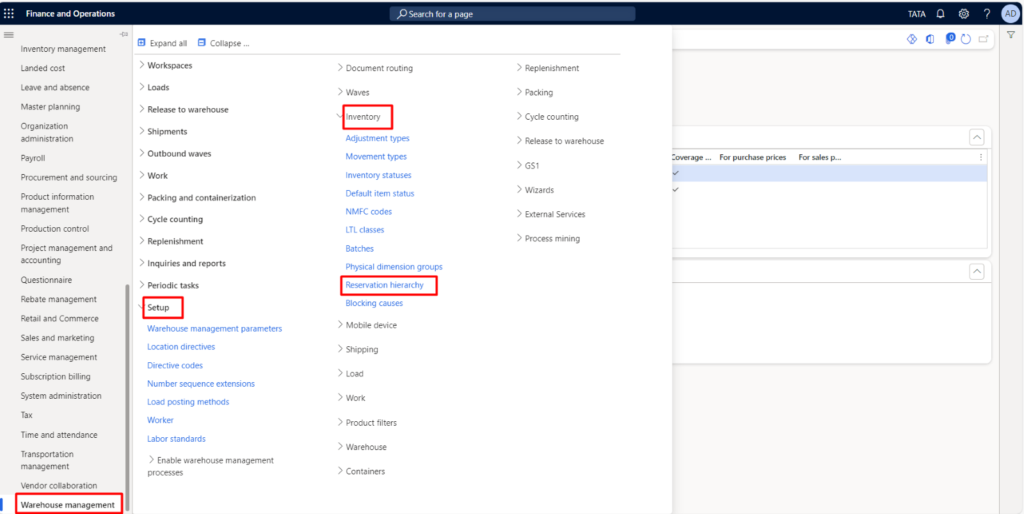

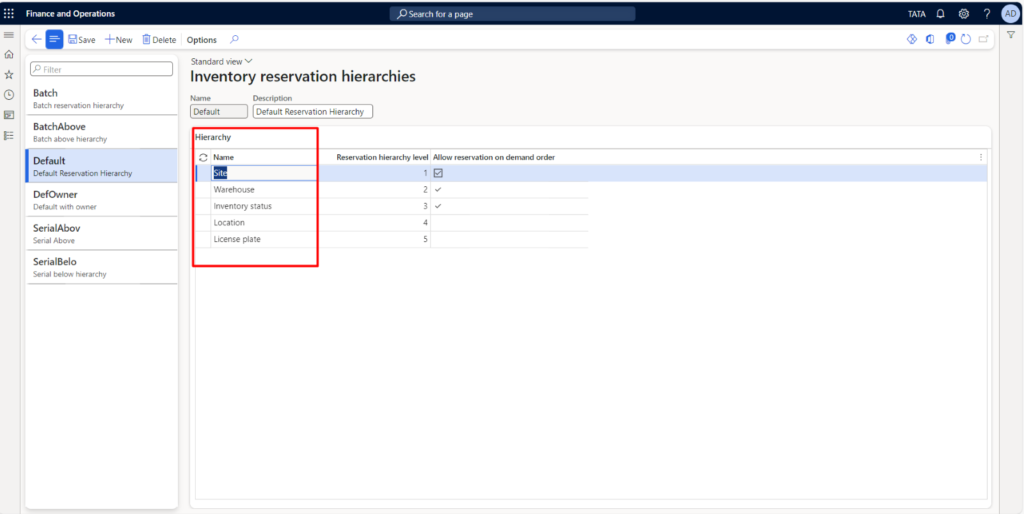

2. Reservation hierarchy

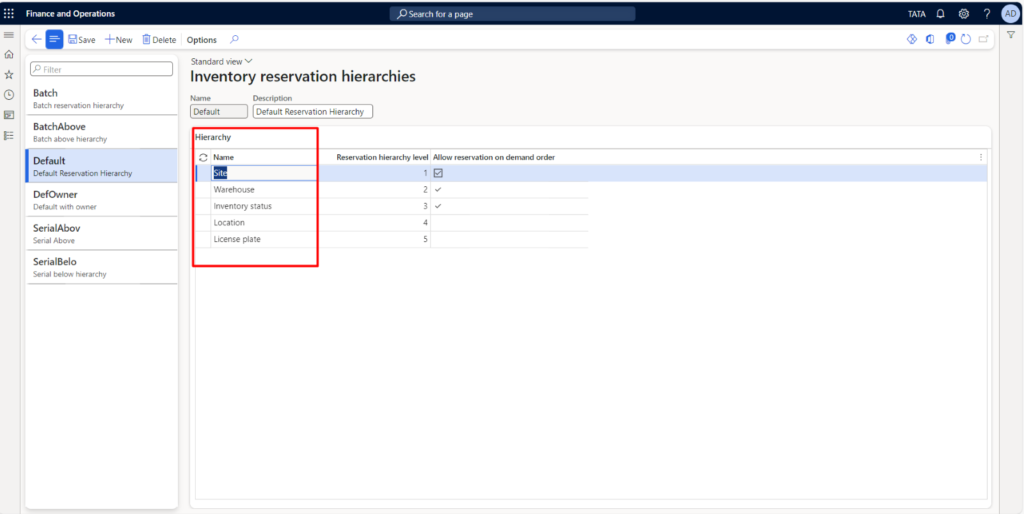

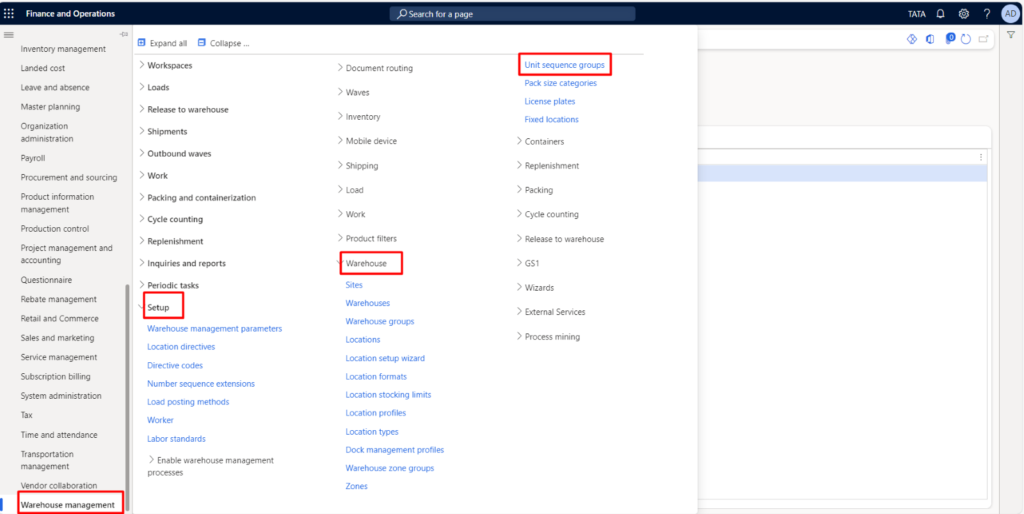

Path: Warehouse Management à Setupà Inventoryà Reservation Hierarchy.

A reservation hierarchy helps delay specific reservation details until after you’ve placed an order. This hierarchy relies on item-related factors like inventory status and license plate for storage and tracking. While it’s essential to have site, warehouse, and inventory status information during the ordering process, certain details like location can be added after making reservations. For instance, the warehouse management system can identify the best locations for picking based on this reservation hierarchy.

3. Unit sequence groups

Path: Warehouse Management à Setup à Warehouse à Unit sequence groups.

Unit sequence group is mandatory setup which works when dealing with movement of material. Now take one example: If the Unit sequence group is mentioned as Each and Box, then While making product receipt from a Purchase Order, mobile device will show the options to receive the materials in two different units which are Each and Box.

Here based on my scenario, I have mentioned the default unit for Purchase orders and Transfer Order as Box.

Now, the Item is ready to use in Advance Warehouse process.

That’s it for this blog!!

How to use this item in actual transaction will be discussed going forward in the blog series.

Keep learning!!!!!

Next in the Blog series:

How to create Warehouses in Advance warehouse management in D365.

How to create Locations in Advance warehouse management in D365.